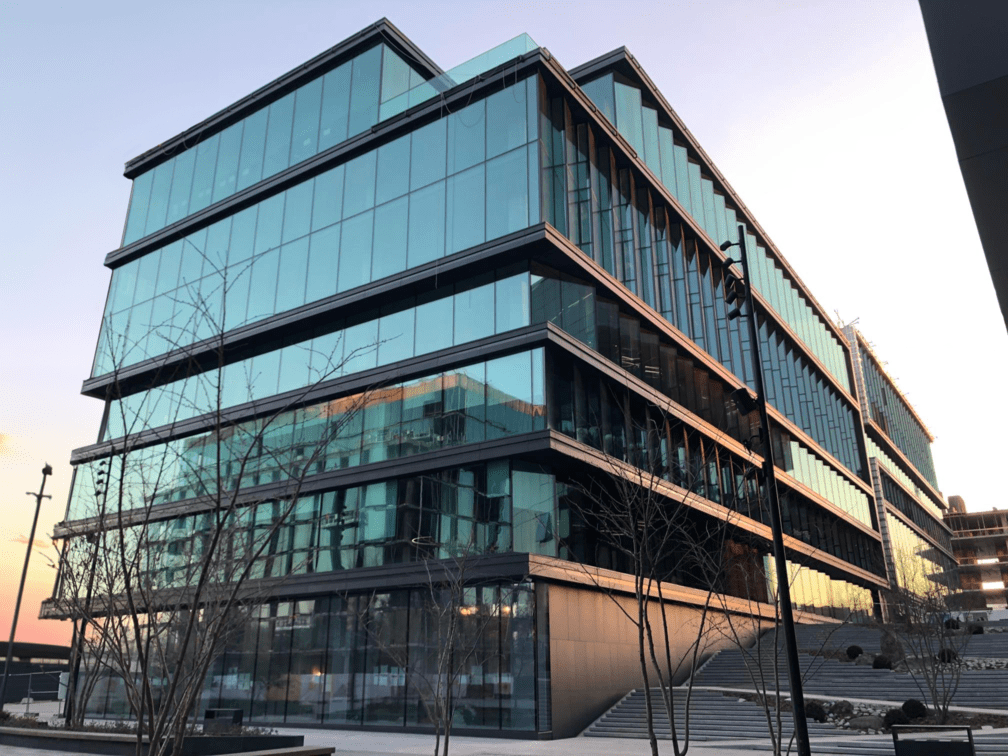

UNIT.City Office, Kyiv, Ukraine

The B14 and B15 buildings project in the innovation park UNIT.City in Kyiv. The main feature is the frameless glass facade and its appearance that changes depending on the lighting.

Aestech

The project was created by the Archimatika bureau, known for its bold projects that combine aesthetics and functionality. The company Aestech supervised the work and offered unique structural solutions, while our partners from the company "Paritet" manufactured them.

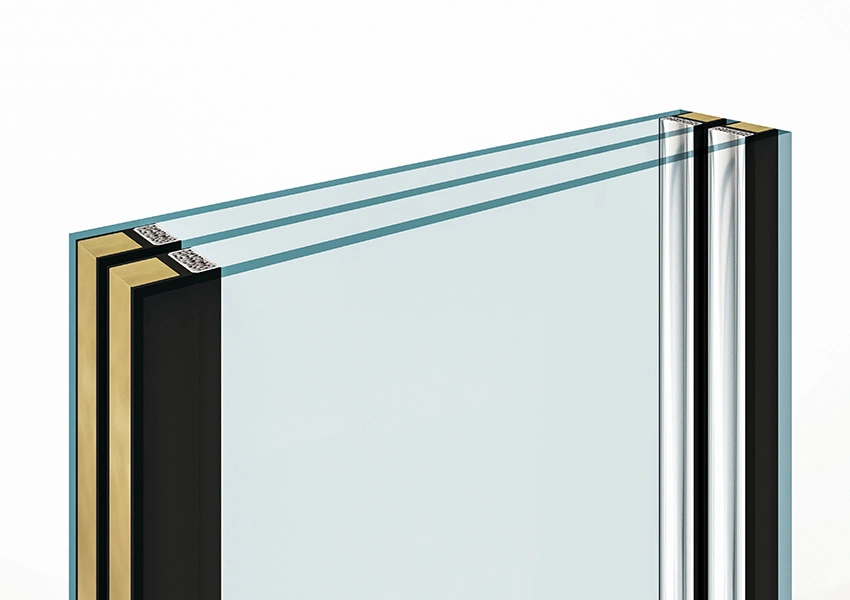

One object, several facade options. According to the architects' concept, the frontal and rear parts were supposed to form a smooth glass wall, while the lateral sides were designed with serrated glass lines. These could have been achieved using traditional aluminum mullion-transom frameworks, but that would have significantly reduced the lightness of the facade. Thanks to the patented frameless glazing technology by Aestech, we easily realized both types of facades without unnecessary bearing structures.

First, we created a trial fragment of the facade that visually demonstrated the capabilities of the technology to the client. It consisted of four glass units and one sash mounted on a metal base.

Next, we conducted an aerodynamic analysis of the building to understand the magnitude of wind loads on the facade and ensure its stability against excessive swaying. We divided the entire facade into "wind zones" based on pressure and selected glass units according to the load requirements.

The installation work was carried out by two companies. One of the subcontractors had previous experience only with facade systems using mullions and transoms. Initially, their team found it unusual to install our high-strength glass units (HSU). However, in a short time, they grasped the principles and were impressed by the speed and capabilities offered by the Aestech technology. For example, the structural features of the HSU allowed them to begin the installation process even with at least one completed floor and do it non-sequentially. This was the case at the B14 and B15 site: the installation work started not from the first floor but simultaneously from the second and third floors.

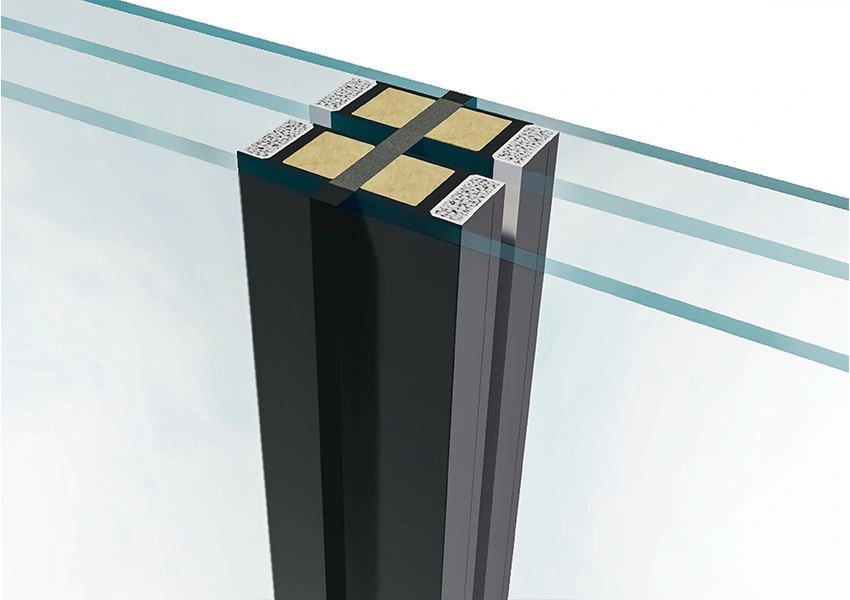

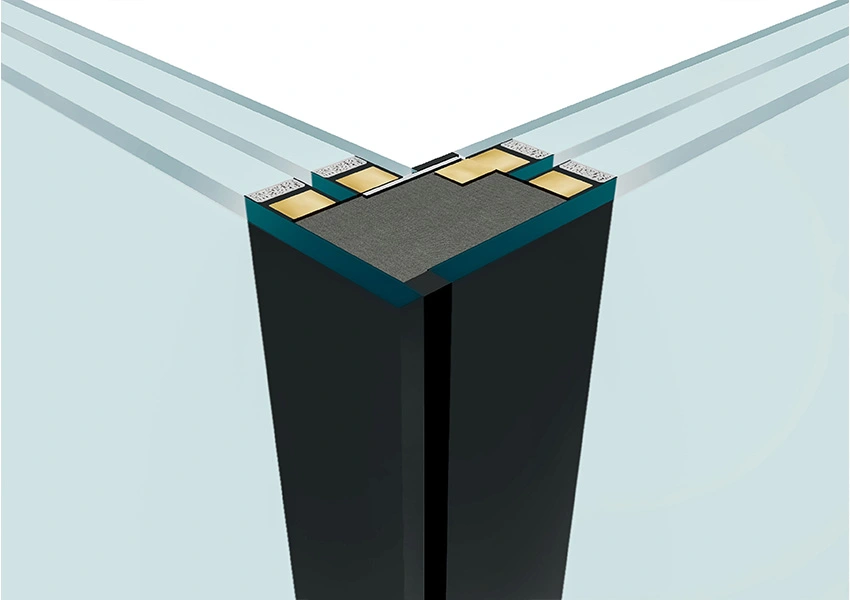

Another special feature is the size of the glass panels. The largest ones measure 5.2 meters in height and 1.8 meters in width. Even with such dimensions, and taking into account wind loads, the structure does not have frames or metal support elements. This not only lightens the facade and makes it more aesthetically pleasing but also significantly improves energy efficiency indicators. These double-glazed units have an additional GRP-profile strip made of pultrusion.

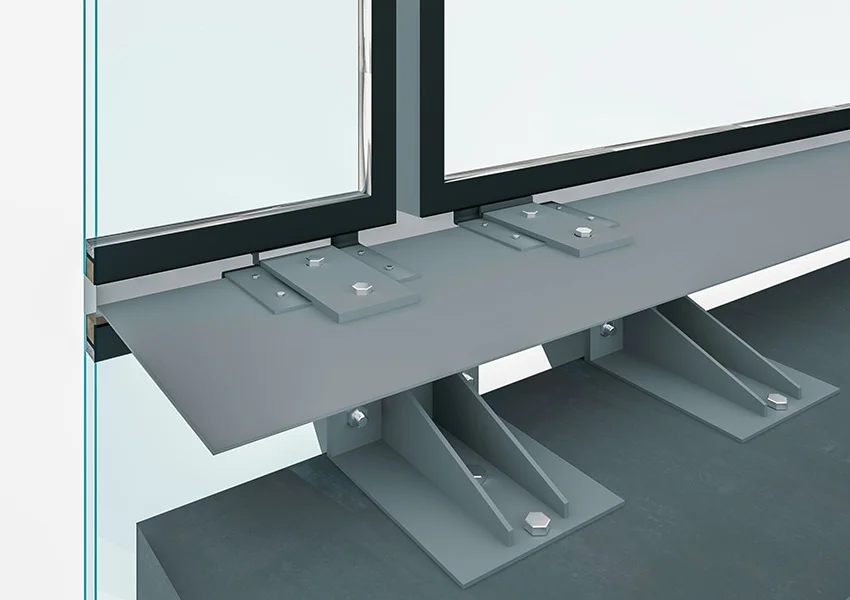

The "double" flat facade on the upper floors consists of two glass panels placed on top of each other. The lower row of glass panels is fixed on projecting brackets, and metal angles attach its upper edge to slots cut in the GRP-profile. The GRP-profile hooks are fastened to the same brackets. The upper row is mounted in a similar way. Between them, there is a 20 mm thick sealant joint. Thus, it didn't matter which row — upper or lower — to install first.

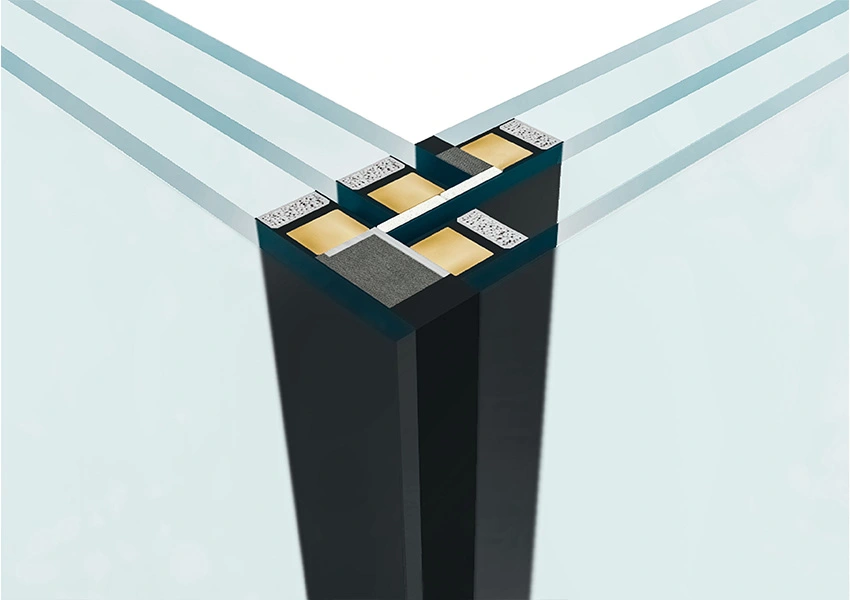

On the "toothed" side of the facade, the glass panels are placed at a 90° angle. This solution has both aesthetic and practical explanations: in certain parts of the toothed facade, ventilation vents are incorporated. The glass panels simply stand next to each other without being mechanically connected. Insulation is additionally applied to the corners and covered with sealant on top.

No aluminum columns, no time wasted on their prior installation. Less heat loss and better sound insulation. And at the same time, a metal-free additional interior space, visual lightness, and true transparency.

In summary, the main element, an insulated glass unit with higher stiffness, can be integrated into various openings without additional supporting structures and directly fixed to the composite reinforcement contour. This allows for the creation of inclined and volumetric translucent structures, as demonstrated by the project for UNIT.City.

In 2022, the B14 and B15 building project made it to the shortlist of the World Architecture Festival 2022 in the Future Projects category.

By the way, Aestech had its stand at the World Architecture Festival 2022, where we explained and showed our projects and patented technologies in detail, and received many positive reviews from the international architectural community.

The World Architecture Festival is one of the key events in architecture and development. Being shortlisted for the competition of this level is a marker that we are on the right track, and our solutions help architects implement big and bold projects.

Leonid Lazebnikov, CEO

Recall that Aestech is a manufacturer of insulated glass units with higher stiffness, which are the basis of Aestech's patented technology of frameless glazing of facades. The company is part of the international holding TECHIIA and was created as a result of the purchase of PROJECTS ENGINEERING CONSULTING GROUP, which has been manufacturing and installing large-format insulated glass units with higher stiffness for more than 10 years.

Our Projects