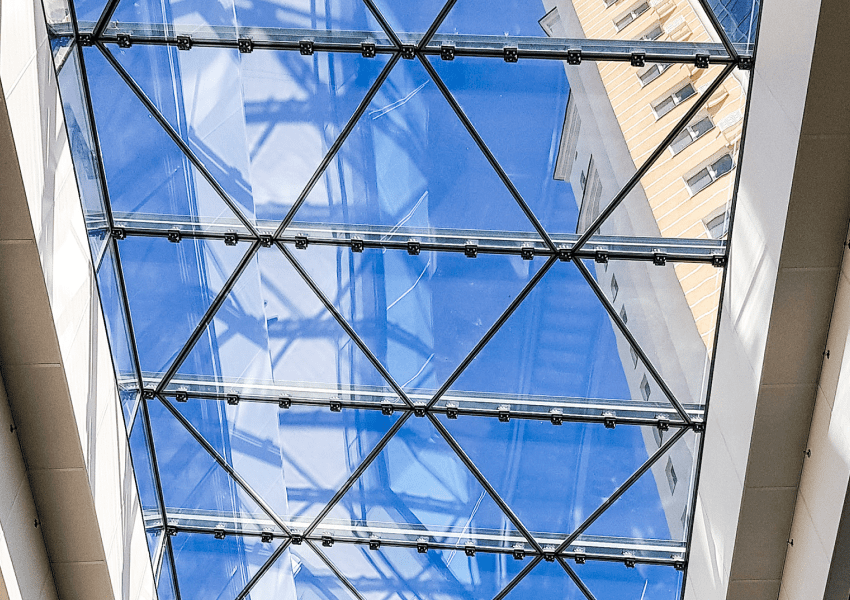

Dome covering of Smart Plaza Polytech shopping center, Kyiv, Ukraine

A record for dome structures - the size of individual transparent elements of the dome covering is more than 4 sq. m. An elegant solution that attracts the attention of visitors.

Aestech

The project of a dome covering for the Smart Plaza shopping center. The key feature is the unusually large distance between the supporting beams and the use of triangular glass units for the roof. Aestech company created the project sketch, supervised the work, and offered structural solutions.

The dome covering for Smart Plaza is the first project of its kind for us, and it immediately became one of the record holders in its class.

The unique feature of this covering is that the supporting metal structure in the form of П-shaped, unconnected beams is located not beneath the glass surface but above the glass units, in the cold zone.

The total area of the roof covering of the four structures is 244 square meters, and the vertical glazing – 106 square meters. The transparent glass elements are located at a height of 7 meters from the floor level and positioned at an angle for proper water drainage.

We wanted the structure to be not only functional but also aesthetically pleasing, in line with the architectural design by the company "Design-Studio" AV Group. Therefore, we increased the spacing between the supporting beams to 2 meters. Less metal structure means more lightness, more light, and more freedom.

A two-meter spacing is atypical for dome coverings. Usually, the distance between the beams is 1 meter, rarely 1.5 meters. Each additional centimeter of distance increases the likelihood of the glass cracking under its own weight. However, insulated glass units of higher stiffness (IGUHS) reduce such risks almost to zero.

The structural features of IGUHS allow them to withstand much greater loads, even despite a larger area. The secret lies in the fact that, unlike standard glass units, our layers of glass are rigidly bonded using composite technology: high-strength adhesive through a pultruded frame.

The roof covering obtained additional structural capacity through the chosen shape of the glass units. A triangle is the most rigid geometric shape, so the horizontal covering consists of glass units that are almost perfectly triangular in shape. They are fixed at three points and additionally attached to glass-reinforced plastic suspensions.

Since temperatures in winter and autumn can be quite low, it was necessary to install glass units in a way that would prevent the structure from freezing. We chose GRP for its good structural strength and resistance to freezing, ensuring that the structure remains free from icicles, condensation, and additional cooling of the interior.

The structural features of insulated glass units of higher stiffness also greatly simplify the installation process. A real case on the construction site: the contractor didn’t manage to align the beams in one parallel plane. In such a situation, ordinary glass units would need to be aligned in the existing plane, or the metal structure itself would have to be leveled. However, for the installation of IGUHS, there is no need for metal profiles or brackets, and they are not affected by inaccuracies in the metal structure. High-strength glass panels of any shape can simply be placed, attached to each other at any angle, and/or gaps between them can be sealed. And so, your covering is ready.

In 2022, the first international presentation of Aestech technologies occurred during the World Architecture Festival. It was the first time the world witnessed the capabilities of frameless glazing technology based on insulated glass units with higher stiffness. Aestech impressed festival attendees with its booth, featuring a massive all-glass arch as the central element.

In 2023, Aestech is once again introducing The Futureglass Prize at the World Architecture Festival 2023.

This special award at the festival will recognize the best projects using glass and innovative methods of its application in architecture. One of the seven projects shortlisted for The Futureglass Prize in 2023 will receive this special award.

The World Architecture Festival is one of the key events in architecture and development. Being shortlisted for the competition of this level is a marker that we are on the right track, and our solutions help architects implement big and bold projects.

Leonid Lazebnikov, CEO

Recall that Aestech is a manufacturer of insulated glass units with higher stiffness, which are the basis of Aestech's patented technology of frameless glazing of facades. The company is part of the international holding TECHIIA and was created as a result of the purchase of PROJECTS ENGINEERING CONSULTING GROUP, which has been manufacturing and installing large-format insulated glass units with higher stiffness for more than 10 years.

Our Projects