Facade systems based on glass-composite structures

Addressing stereotypes

Aestech News

Associative thinking is our gift and curse at the same time. We ask for a Xerox copy, even though we understand that the copying machine may be made by a different company. We call an off-road vehicle a "Jeep," even when it has a different logo on it. This mechanism saves mental energy but sometimes distorts reality and hinders our ability to see ways to improve it.

Similarly, we often imagine translucent façade constructions stereotypically. The common association is with aluminum profile systems of racks and transoms that form a regular grid filled with glass units. It's no wonder — such a solution has stood the test of time and has countless advantages. But it is not without its drawbacks.

In this case, can we create a new system that preserves the advantages but overcomes the shortcomings?

Let's explore.

Step one: Examine the shortcomings of traditional constructions.

The first and foremost disadvantage of aluminum systems is their high thermal conductivity. It is higher than the thermal conductivity of:

- steel by 5 times;

- stainless steel by 15 times;

- glass by as much as 200 times.

| Material | Thermal conductivity, W/(m*K) |

| Aluminum | 202-236 |

| Unalloyed steel | 47-58 |

| Stainless steel (austenitic) | 15 |

| Glass | 1-1,15 |

| Thermal conductivity of materials |

As a result, all aluminum constructions are made with thermal breaks. These breaks take the form of form of GRP inserts between the external and internal contours of the structure in window and facade systems. However, even with such elements, aluminum constructions remain the most problematic areas of translucent enclosing structures in terms of thermal engineering.

The second disadvantage is the coefficient of linear expansion. This is why compensatory measures must be taken in facade aluminum constructions, such as gaps between system elements. It makes it impossible to connect the parts of the system rigidly. Another compensatory step is including a large number of rubber and plastic seals in the system. They allow for the compensation of displacements of different elements in case of significant temperature fluctuations ranging from -35 ℃ to 90 ℃.

| Material | Coefficient of linear thermal expansion 10-6 °C-1 |

| Aluminum | 22.5 |

| Concrete | 14.5 |

| Polyvinyl chloride (PVC) | 50.4 |

| Steel | 13.0 |

| Stainless steel (austenitic) (304) | 17.3 |

| Window glass (mirror, sheet) | 9.0 |

| The coefficient of linear expansion |

The third disadvantage is a high tendency for condensation formation in closed profiles. It creates additional difficulties related to its removal. It is particularly challenging to do so in structures located at non-right angles and in dome systems.

Step Two: Seek Alternative Options

Over the years of experimentation, engineers have developed a range of promising materials that compete with aluminum and steel. One such material is GRP, a high-strength and lightweight composite material made from glass and plastic. Using the pultrusion process, where the raw material is drawn through a heated die to a temperature of polymerization, you can create an almost unlimited range of profiled products.

By the way, in one of the documents, you often come across the term "pultrusion materials," which means materials that have specific characteristics such as hardness, elasticity modulus, absorption, and so on.

The variety of pultruded profiles produced allows for solving most window and facade glazing tasks.

For example, solutions developed by Aestech company have been successfully implemented in projects from 2016 to 2021. Let's talk about some of them.

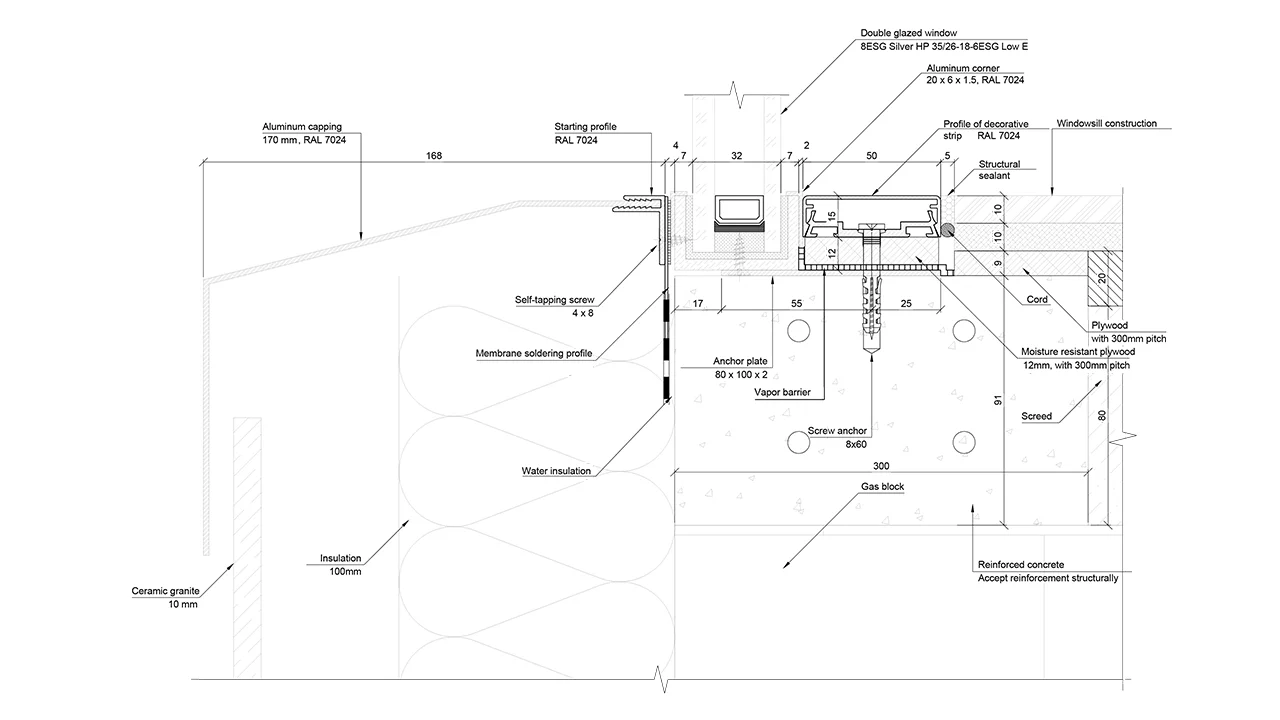

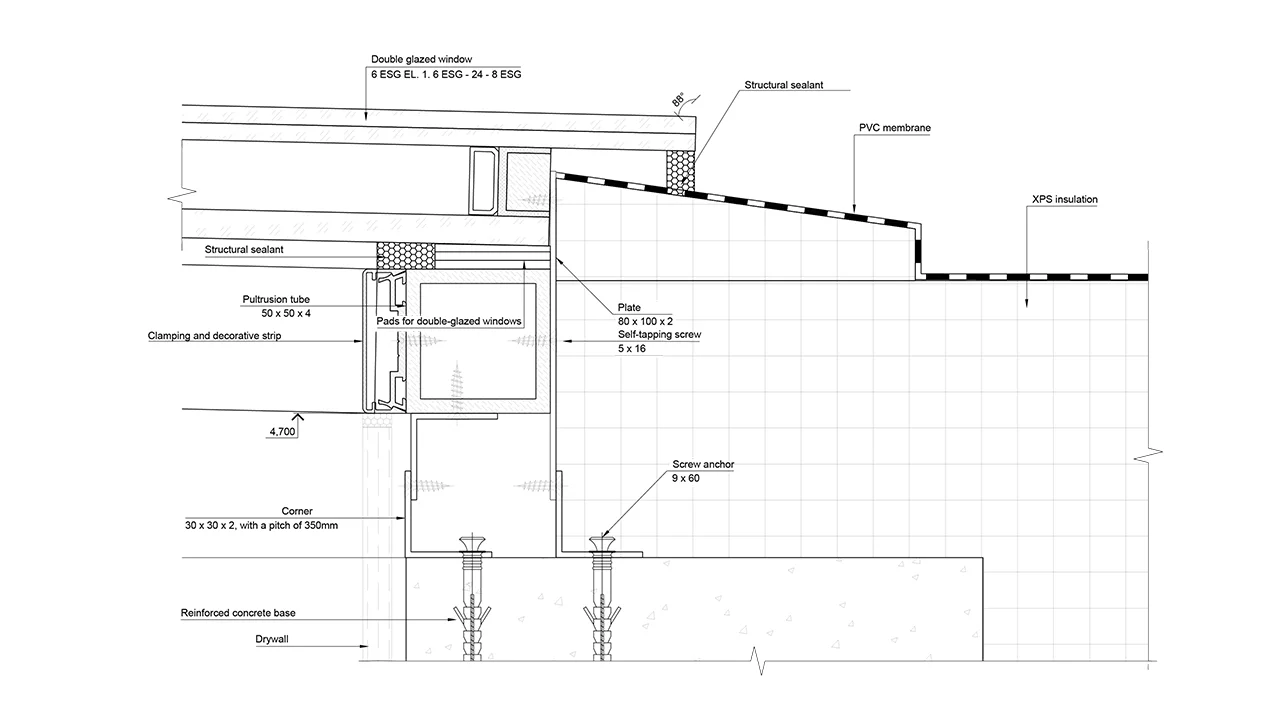

A complex system of connections to transparent structures of facade decoration made of natural slate. The task was to minimize the visible structures of the translucent elements. A large-format glazing system based on a P-shaped (channel) pultruded profile was used, allowing the facade decoration elements to be brought directly to the translucent elements. The scheme for installing a glass unit in a system with a pultruded profile is shown in the figure.

Due to the absence of closed profile systems (tubular cross-section), the system is not prone to condensation formation. Therefore, it is unnecessary to drain it, and opaque elements can be brought directly to the glass.

Also, pultruded elements were used to accommodate horizontal transparent features — a large-format transparent roof.

Due to the low thermal conductivity of pultrusion (thermal conductivity is equal to that of wood), pultruded profiles provide high thermal performance characteristics at the joint and prevent condensation. A separate aspect of ensuring the sealing of the joint zone for the roof is the development of experts from Aestech. By issuing about 100 mm around the perimeter of the outer glass in a high-strength insulating glass unit, it allows for the installation of a waterproofing layer of the roof, which ensures a 100% absence of leaks.

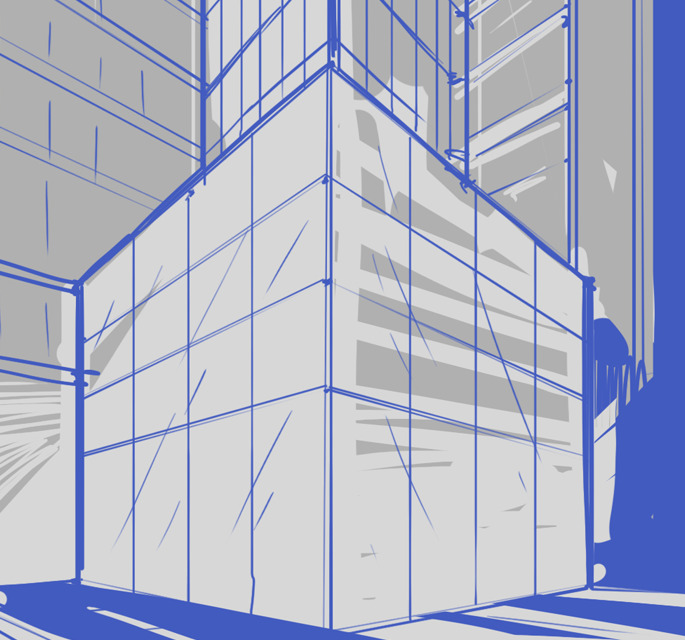

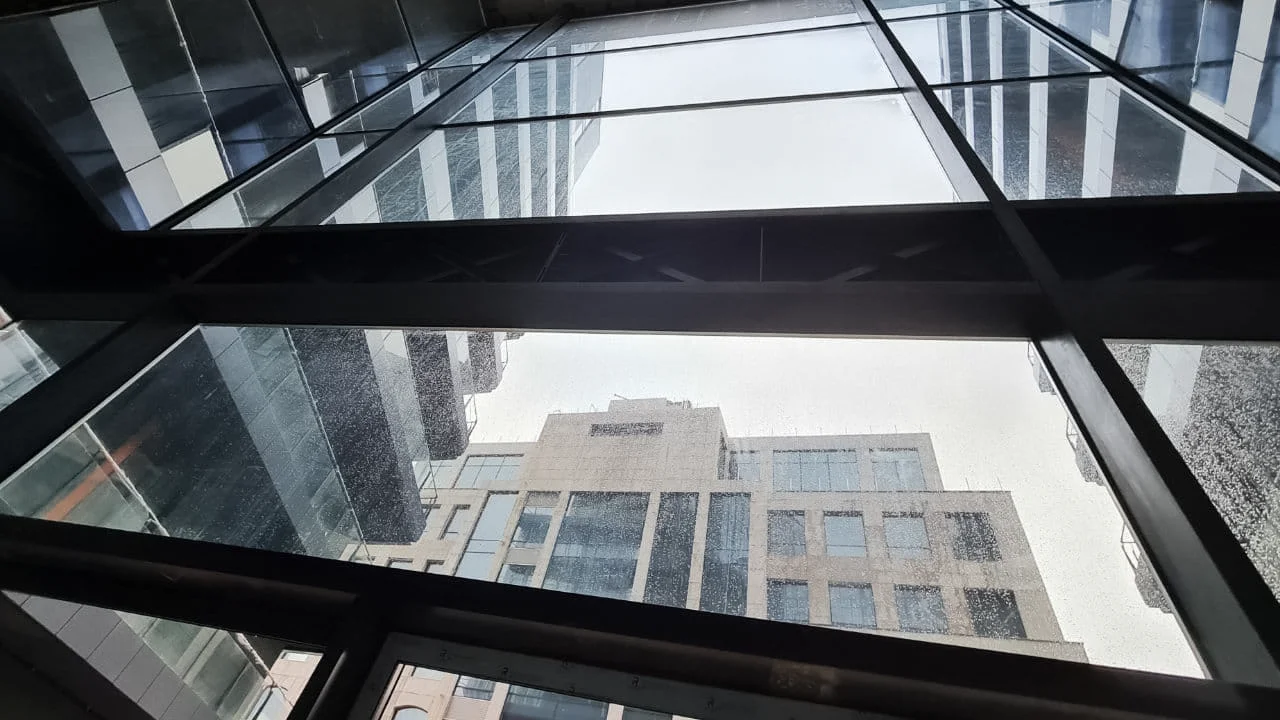

The next project is an office center in Kyiv, which became a new stage in Aestech's design of composite material facade systems.

The task was to glaze a 12 m high facade system for the entrance group.

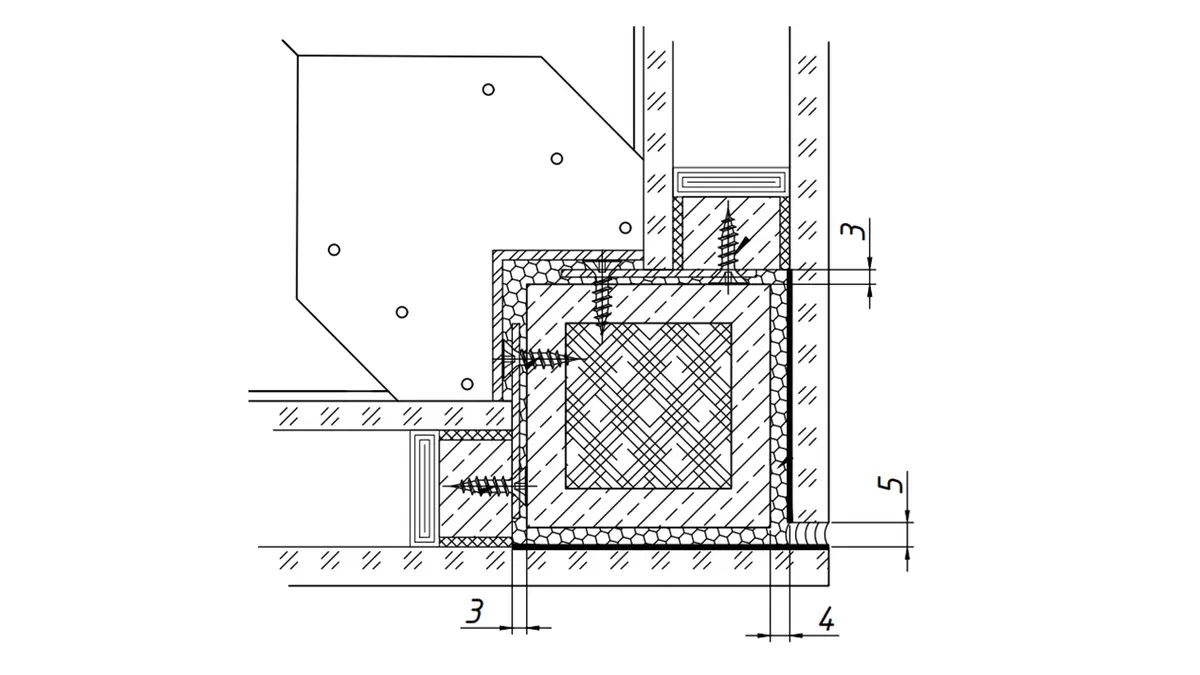

Large-sized insulated glass units of higher stiffness (Aestech's proprietary technology) were attached according to the principle of a cassette facade. It means that the insulated glass units were fastened to the vertical support elements, made of a specially manufactured pultruded tube with a cross-section of 50 x 50 x 8 mm, hidden in the corner joint of the glass units.

The scheme of the corner joint of the insulated glass units is shown in the figure.

With this solution, the structure acquired delicacy and transparency for the architects. And the customer received an exclusive energy-efficient solution that complemented the modern architectural ensemble of the new office center.

Both architects and customers set themselves the task of combining the elegance of the structure with its high thermal and other operational properties. The use of composite glass structures with solutions from Aestech opens up new horizons for them.

AR&D (Analytical Research and Development) Aestech