Where do optical distortions on glass facades come from and how can they be avoided?

Glas units without optical defects are no longer a myth.

Aestech News

Walking around a big city offers a diverse aesthetic experience — and, unfortunately, sometimes an ambiguous one. Especially when you are looking at buildings with large-format facade glazing based on multifunctional glass. This solution has excellent thermal performance as well as increased reflectivity.

And here lies the reason for our aesthetic dissatisfaction. Instead of a facade that reflects the surrounding world evenly, we usually see a grid of curved mirrors. Why does a good architectural idea turn into such a harsh reality?

Optical defects can have technical origins. For example, they may occur during the tempering process of glass, when the so-called “waviness” is formed. Due to an incorrectly chosen temperature for the tempering machine, the glass sags on the rollers and acquires a sinusoidal shape. And at this point, there is no way to fix it.

Such defects occur in low-cost constructions or temporary structures of non-critical importance. The good news is that these cases are becoming rare as the quality of tempering machines improves along with the qualifications of personnel. The bad news is that the production chain still has weak links.

There is another reason for distortions. These are optical defects that occur during the assembly and use of glass units. Let’s discuss them in more detail.

Examples of optical defects

Let's start with the assembly of double-glazed windows, the selection of the number of chambers, and how all of it affects optics and thermal physics

To determine the geometric parameters of the glass unit, we used the MERLIN device. It allows us to obtain absolute values of glass thickness, the position of the coating, and the distance between glasses in different zones of the glass unit using a laser beam.

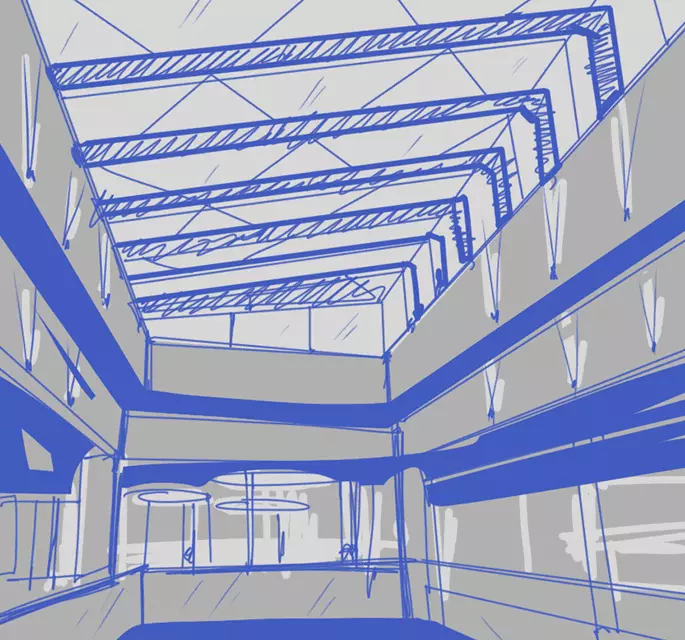

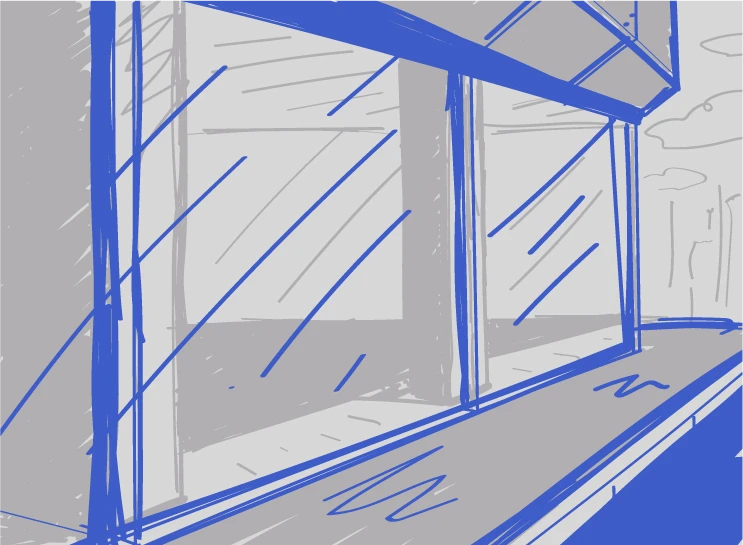

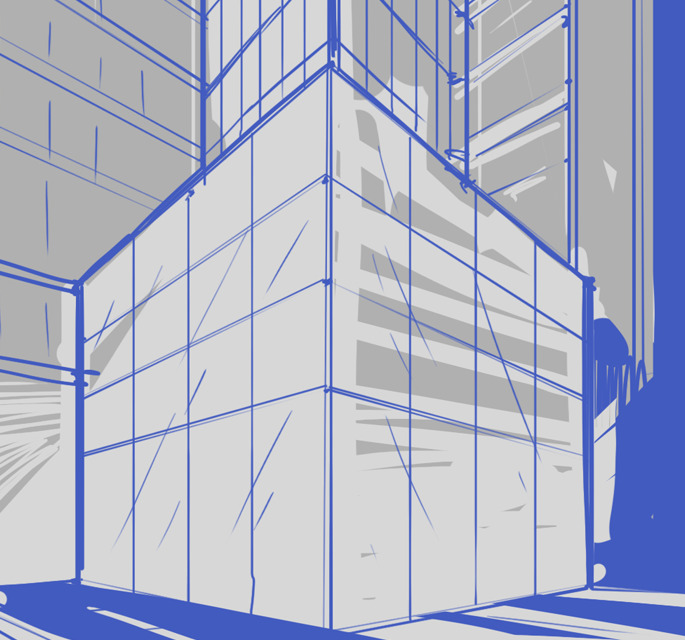

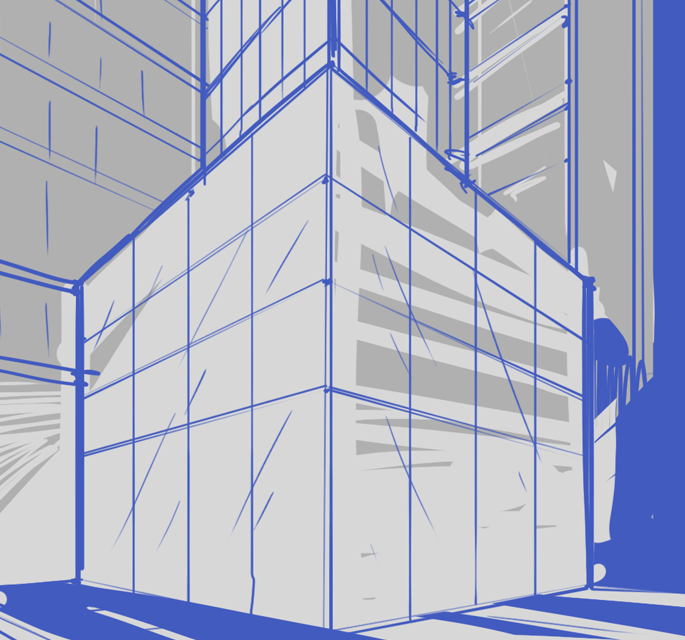

To better understand the problem of significant optical distortions on double-glazed windows, let's look at examples in the photo.

The distortions on these facades are noticeable to the naked eye, despite one of the main architectural requirements for a translucent structure being the ability to obtain reflection without distortion. This creates an aesthetic impression that subconsciously affects the positioning of the object in a particular reputational and price category.

The distortions shown in the photo are even present on smaller-sized glass units. If you enlarge them (which is a trend, architects sometimes include glass units with an area of over 10 square meters in their designs), the result will be unsatisfactory. These distortions become even more significant, with layers collapsing within the double-glazed windows and even destruction occurring.

Where do distortions come from?

To identify the source of distortions, experts from Aestech conducted empirical and calculational studies on a standard double-glazed window and an insulated glass unit with higher stiffness (IGUHS). The latter is a development of Aestech and is designed for use in large-format translucent facade systems.

The “lensing” and “collapsing” effects in glass units are directly related to "climatic" (internal) load. This refers to the increased or decreased gas pressure in the double-glazed window compared to the initial pressure at the time of manufacture. Changes in gas pressure in the glass units are caused by climatic conditions during use, such as air temperature, changes in pressure with altitude, and fluctuations in barometric pressure.

European standards (EN) pay much attention to the value of the climatic load and the need to take it into account in different cases. According to EN13474-1, the climatic load can reach +20.4 kPa and –23.4 kPa. These figures are calculated for European climatic conditions. However, with a combination of factors, the internal load in our climate can reach –33.7 kPa in winter and +20.8 kPa in the warm season.

From the moment of sealing the double-glazed unit, the internal load puts pressure on the glass and deforms it. As the glass deforms, the internal volume changes. The change in internal volume is associated with internal pressure and is described by the Mendeleev-Clapeyron equation.

As the temperature does not change significantly in this case when the volume and pressure are altered, the temperature can be considered constant. Therefore, if the internal volume increases, the internal pressure decreases. That means that the presence of deformations affects the magnitude of the load. The load is perceived in two ways simultaneously. Part of it is due to the resistance of the glass to deformation, while the other part is compensated for by the change in gas volume during glass deformation.

It is believed that in conventional double-glazed windows, wind load is only absorbed by the outer glass. The inner layers, due to their structural properties, are considered "parasitic" and are only intended to affect the thermophysical characteristics of the glass unit. Therefore, if the double-glazed is hinged on all sides, this statement is true.

The idea of an insulated glass unit with higher stiffness (IGUHS) is to force the "parasitic" inner glass layers in the double-glazed window to participate in the overall resistance to the wind flow. In other words, a conventional double-glazed window is transformed from a spherical shape (where the layers of glass can slide freely against each other) into a tubular one.

The latter implies that the glass is rigidly glued together through an enhanced distance based on profiled composite solutions and special high-adhesive glue mixtures. Thus, in order to structurally increase the stiffness of the insulated glass unit, it is necessary to replace the volume of secondary sealing with a rigidly glued composite profile of a rectangular cross-section in a conventional glass unit.

Methods for calculating the stress-strain state of glasses in a conventional double-glazed unit (for example, SJ MEPLA) are based on the assumption of hinged fixation of edges. They cannot be applied to calculate the IGUHS produced by Aestech because practically rigid fixation is required for such calculations. However, in any case, before starting to calculate the insulated glass unit, it is necessary to calculate the climatic load — excess pressure in the glass unit.

A. Yu. Kurenkova, A. V. Kuzmenko, and O. M. Kurenkova in their article "Insulating glass formula for high-rise buildings" (Engineering and ConstructionJjournal, №8, 2011) provide data obtained from the method of calculating excess pressure in the double-glazed window. Based on this data, the static strength of insulated glass units under the influence of climatic load was determined for conventional insulated glass units (CIGU) and insulated glass units with higher stiffness (IGUHS). From this, three other aspects are of interest to us:

1. The nature of the pressure distribution in single-chamber windows differs significantly. For the CGU the angular zones are more loaded, and for the IGUHS — marginal zones.

2. The level of pressure in the inner glass of IGUHS is higher than in the CGU by approximately 20%, which confirms the idea of involving the inner glass in the overall load resistance.

3. Under the influence of climatic load in the IGUHS, the outer glass (greater thickness) flexes approximately 20% less than in the CGU, and the inner glass (smaller thickness) of the IGUHS flexes approximately 10% more than in conventional glass units.

Therefore, reducing the degree of lensing can be achieved either by increasing the thickness of the outer glass in the CGU, or by using IGUHS.

This is demonstrated by Aestech facade systems that use large-format insulated glass units with higher stiffness.

Reduced lensing levels enable the actual construction to conform to the architectural design and provide an almost distortion-free reflection of the surrounding environment.

Another important factor that cannot be ignored and that is hidden from the consumer's eyes is the technology used in assembling the glass units.

Example: During the inspection of one of the objects, a significant reduction in the airspace was found at an outside air temperature of 25 degrees Celsius. This only indicates that the insulated glass unit (of a sufficiently large size — approximately 4 square meters) was assembled in a horizontal position without compensating for the sagging of the upper glass. What will happen in winter? What kind of thermal physics can we talk about?

Single-chamber or two-chamber units

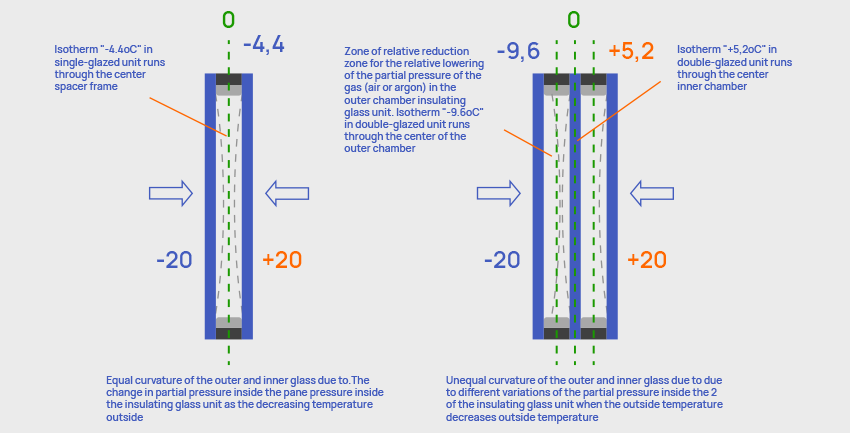

The effectiveness of two-chamber units varies during warm and cold periods. As temperature decreases, the level of distortion in two-chamber units increases compared to single-chamber ones. The reason is a sharp decrease in the partial pressure of the gas (air or argon) in the first chamber at low temperatures, known as the temperature offset effect. If the area of the two-chamber window is larger than 3 square meters and the aspect ratio is less than 2: 1, its effectiveness will decrease. This does not occur during warmer periods. For samples of 350x350 mm, everything works great.

To understand this better, let’s consider a simplified working diagram of single-chamber and two-chamber windows. We take the same glass layers and the same dimensions of the spacer frame. In reality, the glass may be different, including different coating and tinting. The spacer frames are usually also different, but the diagram is simplified for better understanding.

Recently, single-chamber glass units have "grown" in terms of their thermal technical characteristics, creating competition for two-chamber units, particularly in matters of energy efficiency. Other advantages include reduced weight and decreased lensing, inevitably leading to cost savings.

This does not mean that two-chamber glass units should be forgotten once and for all, but it is always worth paying attention to technical characteristics, particularly thermal ones. Scientists and engineers are constantly working to improve the quality of solutions while saving client's money.

Authors of the article:

Aestech design bureau team

Find out about frameless glazing