Energy efficiency of transparent enclosing structures

Digging into confusing terms.

Aestech News

There are not so many utilitarian functions in transparent enclosing structures (hereinafter TES) for construction. The main ones are access of natural light inside and participation in thermoregulation. Today we will talk about the second point.

Without going deep into details, with simple arithmetic and physical efforts, we will try to find out what needs to be done so that the TES retains heat well in winter and reluctantly heats the room in summer.

We want to warn you straight away that, in most cases, we will use the help of system sources of information. To a greater extent, the main source will be K.F. Fokin’s book " Heat Engineering in the Construction of the Enclosing Parts of Buildings."

But first, let's try not to get lost in two aspects of terms that determine the thermal characteristics of structures and materials used for TES.

Mathematics of Winter

The first term is heat transfer resistance. Many private and corporate clients who want to determine the type and characteristics of TES get confused by this term. Should this indicator be small or big? If it is small, how to increase it? And what will this increase bring in terms of economy and ergonomy?

Before giving a basic definition of the term, we want to ask the reader about what they seek to get as a result of installing a good TES. Surely, most readers will say the following – the design must be esthetic, ergonomic, and economical! So, we get three "E’s".

We will leave the first two to the discretion of architects and designers. Instead, we will deal with the third one. Let's leave TES aside for a moment and give an example of another economic indicator.

What is the fuel consumption of your car per 100 km? Most will indicate quite accurately and even boast that their car has a very moderate consumption, and this really affects the cost of operating the car. The car is economical because it consumes little fuel. Everyone understands this — fuel consumption can be converted into money for a certain segment of the journey.

Likewise, we would like to understand how much money we lose through various types of TES and what, in the end, doubling or tripling the value of "heat transfer resistance" gives us. But the fact is that, unlike fuel consumption, this term has neither physical nor economic meaning.

In contrast to our land, European people have not heard of any heat transfer resistance and know nothing about it. For an ordinary consumer, they offer the simple term ‘heat transfer coefficient’ (heat absorption coefficient). In short — "U-value."

"U-value" (W/⁰С)*m2) is measured by the amount of heat that will pass during a unit of time through 1 m2 of the enclosure due to the difference in air temperatures on one and the other side of it, equal to 1 °C.

We take a good look and see that the indicator is very similar to fuel consumption in a car. Everything is clear with it. We know the cost of heat (we pay either for kilowatts or for gigacalories, just like for gasoline), so if necessary, we can easily calculate how much money literally flies out through our TES for heating in winter or cooling the street in summer.

We do not know the name of the person who turned the understandable indicator "heat transfer coefficient" into heat transfer resistance, calling it "R". He did it in a simple but not entirely clear way for the consumer: he took the reciprocal of the heat transfer coefficient, that is, R=1/U. Thus, the unit of measurement of R will be m2*⁰С/W.

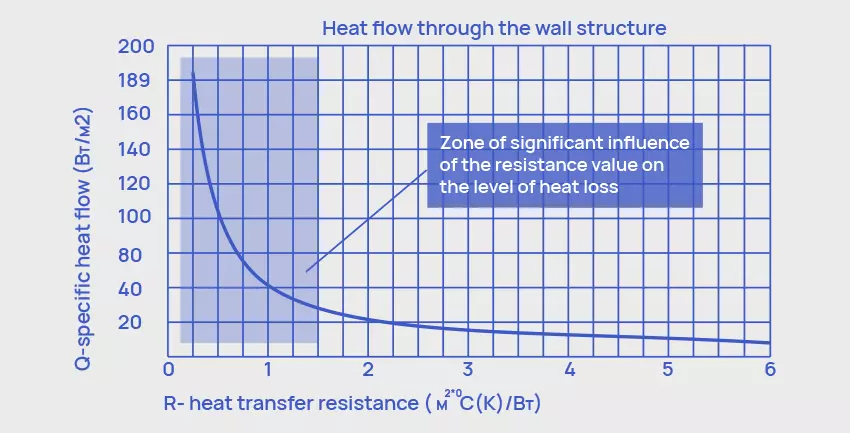

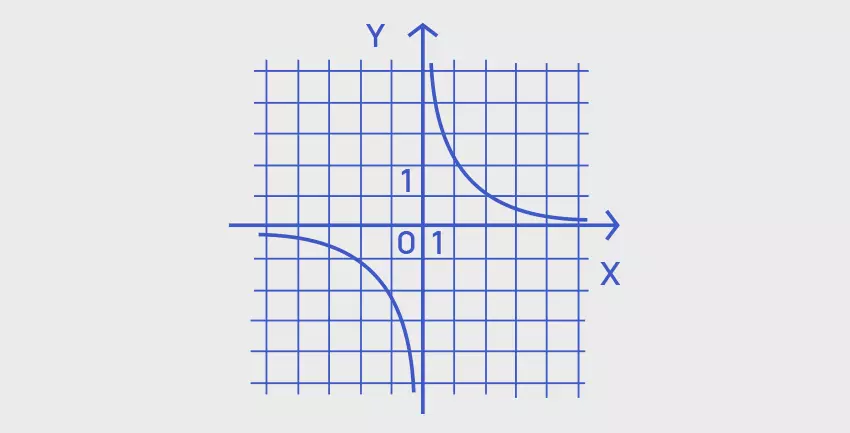

Pretty clear, right? But let's call on algebra to help and look at the function R=1/U — a hyperbola. It is clearly seen that the dependence of U and R is non-linear, with values of U tending to zero and R tending to infinity. So where is the level of reasonable sufficiency when it makes sense to fight for an increase in the value of heat transfer resistance?

Let's look at the graph of the dependence of the specific heat flow Q (W/m2) per hour through TES on the value of heat transfer resistance (m2*⁰С/W). We can see that with an increase in heat transfer resistance from 0.25 to 0.5, there is a sharp decrease in heat loss through TES.

In the case of a further increase in the value of heat transfer resistance, the economic effect of reducing direct heat losses is no longer that obvious. And with heat transfer resistance values of higher than 2 m2*⁰С(K)/W, the level of investments in TES to achieve such a value — and this is already a 3-chamber double-glazed window — will not be able to ensure economic feasibility, since the payback period of such investments from saving heat losses of TES will be be measured in tens (!) of years.

Why, then, for other enclosing structures, the value of heat transfer resistance is at least 3, and even 5 m2*⁰С/W? The answer is simple. Acquiring such values of heat transfer resistance for non-transparent elements (walls and ceilings) is achieved in relatively simple and inexpensive ways, and these structures occupy a much larger area than TES.

To understand the impact of the value of the heat transfer resistance on the actual state of affairs with TES heating technology, let's set a few reference points.

Ordinary glass (single without double-glazed unit): R=0.17 m2*⁰С/W. Losses are about 200 W/m2 per hour through TES with the inside-outside temperature difference of 43 degrees.

Ordinary single-chamber double-glazed unit R = 0.37 m2 * ⁰С / W. Losses are about 120 W/m2.

Thus, we managed to improve the value of heat transfer resistance by a little more than 2 times and saved 80 W/m2 per hour.

We increase the heat transfer resistance to the level of R=0.75 m2*⁰С/ W (the maximum that can be "squeezed" out of single-chamber double-glazed windows today). Losses are about 60 W/m2 per hour. That is, the heat transfer resistance increased by 2 times, and the losses decreased by only 25%.

And if the heat transfer resistance is increased by another 2 times, to the level of R=1.5 m2*⁰С/W (a high-quality double-glazed unit, which increases the cost of the structure by at least one and a half times), the losses reach about 38 W/m2. That is, the savings for doubling the value of the heat transfer resistance is only 22 W/m2 per hour. Compare with the first savings: 80 W/m2, 60 W/m2... and only 22 W/m2. If you calculate the savings from high values of heat transfer resistance to TES, we are sure that you will be very disappointed with the figures obtained.

There is anothother thing that is also important to the consumer. At what value of heat transfer resistance will he be protected from such an unpleasant thing as condensation (fogging) on the glass?

At a maximum humidity level of up to 60% (bath-houses and saunas are not taken into account) for the absence of condensation at the inside-outside temperature difference of 43 degrees (as required by the regulations), i.e. the temperature outside the window is -20 and +23 degrees in the room, the resistance to heat transfer should not be lower than 0.66 m2 * ⁰С / W.

To find out this value, we used the formula for calculating the heat transfer resistance R=1/U.

| Inside temperature °C |

23 |

| Outside temperature °C | -20 |

| Relative humidity, % | 60 |

| The heat transfer resistance of a double-glazed unit must be over: 0.656 m2 °C/W |

αint = 8 — the heat transfer coefficient of the inner surface of the enclosing structures, W/(m2°C), adopted according to DBN V-2.6-31-2006 Appendix E. The result of the online calculation is shown in the graph.

Therefore, in order to prevent fogging or condensate at sufficiently critical levels of temperature difference, a single- or double-glazed window with a heat transfer resistance value of not more than 0.7 m2*⁰С/W is sufficient. And direct losses through such a TES will be about 70 W / m2. Knowing the TES area, it is already easy to calculate the level of costs for compensating for the losses of TES during the most critical periods of temperature fluctuations.

Important note: European standards take into account the temperature difference between the street and the room by only 15 degrees (while we have 43 degrees). Therefore, the use of the values of the heat transfer coefficient specified in European certificates for a comparative assessment of the thermal characteristics of TES produced in Ukraine is incorrect.

Mathematics of Summer

So, we figured out how to protect ourselves from the cold. Now let's try to escape the heat.

It should be noted that the climate in Ukraine is continental, and summer temperatures are quite high. They are not as critical as frost (much less scalded than frostbitten), but to ensure the comfort of staying indoors, we use air conditioning systems. To help them — special reflective types of glass, which significantly reduce the amount of solar thermal energy entering our premises through TES.

Any expert in the field of climate technology will tell you that the cost of cooling by 1 degree is twice as expensive as the cost of heating the same room by 1 degree.

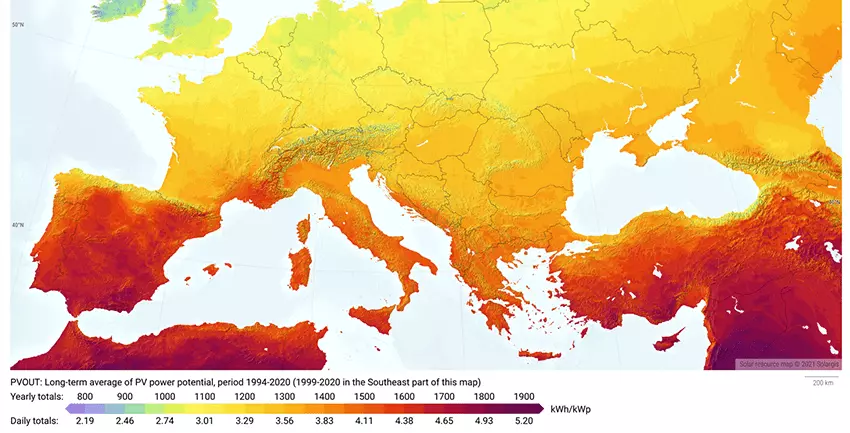

If we look at the solar radiation map, we will see that Ukraine is located in the zone of receiving approximately 100 kilocalories per 1 square cm per year, provided that the rays fall at an angle of 80-90 degrees to the Earth's surface. Let's convert the area of 1 square meter into square centimeters and get a value of 10,000 square centimeters. The total amount of solar radiation received per year per 1 square meter is equal to 10,000,000 calories or 10,000 megacalories, which in conversion (1mCal = 1.16 kW) gives 8600 kW.

In summer, the amount of solar radiation is 25% greater than in winter. That is, it can be assumed that in the summer the amount of solar radiation per 1 sq. m will be 3.75 kW. Taking into account the fact that the maximum activity of the sun is from 10 a.m. to 4 p.m. in summer, the specific solar radiation input will be within 600-800 W/h (min-max) per 1 sq.m. Let's introduce a reduction factor for the standard heat-technical properties of a double-glazed unit without protection from solar energy — 1.15 (15%) and a factor for indirect sunlight exposure of 1.3. The total decrease in the level of thermal energy will be 1.5 times.

Therefore, the maximum amount of solar radiation will not be within the range of 500-550 W/hour, penetrating through 1 sq.m of TES on the hottest sunny day, but to compensate for it, at least twice as much energy for air conditioning of the room is required.

With the help of modern energy-efficient glasses, it is possible to reduce the level of solar radiation penetrating through TES by 4 times (solar factor SF = 0.25), which ultimately will lead to the penetration of solar energy into the room through TES of only 130-140 W/m2 instead of 500 W/ hour.

If your TES have direct exposure to solar energy, we recommend that you include outer glass with good reflective characteristics in the composition of the double-glazed window, or multifunctional glass, which is even better. It will remove solar heat in the summer and significantly improve the thermal performance of the double-glazed unit in the cold season.

We tried to set out in a fairly concise form the main principles affecting the choice of SPOK. We hope that with the help of an ordinary calculator and simple formulas, consumers will be able to evaluate the effectiveness of investments in various types of translucent structures and combine all three “E’s” in them. Let’s name them once again: Esthetics, Ergonomics and Economy. May your homes be light, warm, and cozy!